Projects

The challenge and the solution

The small footprint botanical like Organica solution solves a problem which arises with the massive urbanization we are experiencing today.

Conventional wastewater treatment plants are large and unpleasant facilities, typically built in the outskirts of cities. At the same time water scarcity becoming a pressing issue and it becomes clear that water needs to be recycled. Pumping the wastewater overlong distances to tradition treatment plants outside the cities and then pumping back the recycled water consumes lot of energy and is not a sustainable practice.

The Organica solution was developed to address this challenge. Our goal was to create a much smaller footprint garden-like water treatment facility that is seamlessly integrated – technologically, architecturally, and psychologically – into residential and commercial environments.

Today over 120 projects around the world prove the advantages of this approach. Organica facilities can be implemented in all kinds of climates and in capacities anywhere between 1000 – 200 000 m3/day.

Our solution is based on two important pillars:

- a process which incorporates natural elements to form superior biofilm characteristics. As a result, the fixed films used in Organica facilities feature much more diversity and stability than traditional ones.

- tight disciplinary integration fitting into the urban fabric requires more than a good wastewater treatment process. Much broader considerations including urban planning, architecture, smell, aesthetics, and psychology are required. Therefore, a much higher integration is ensured between process-, civil-, mechanical-, electrical engineering, architecture, landscaping, and botany.

organica facilities incorporate natural processes and architectural principles

Advantages

UP TO 60% SMALLER PHYSICAL FOOTPRINT

The efficient process produces larger biomass/m3 of reactor which leads to smaller overall reactor size. This combined with a creative architectural design results in 60% smaller physical footprints than an activated sludge design for the same application.

30% OR GREATER REDUCTION IN OPERATING EXPENSE (OPEX)

In an Organica facility, almost all the biomass is fixed on the natural (plant) and engineered root structures, resulting in low suspended solids throughout each stage of the treatment process. The cleaner water (low TSS) results in highly efficient oxygen transfer rates, thereby lowering aeration requirements, which is the most energy-intensive part of any aerobic treatment process. The result is a 30% or greater reduction in electricity consumption compared to other activated sludge-based solutions.

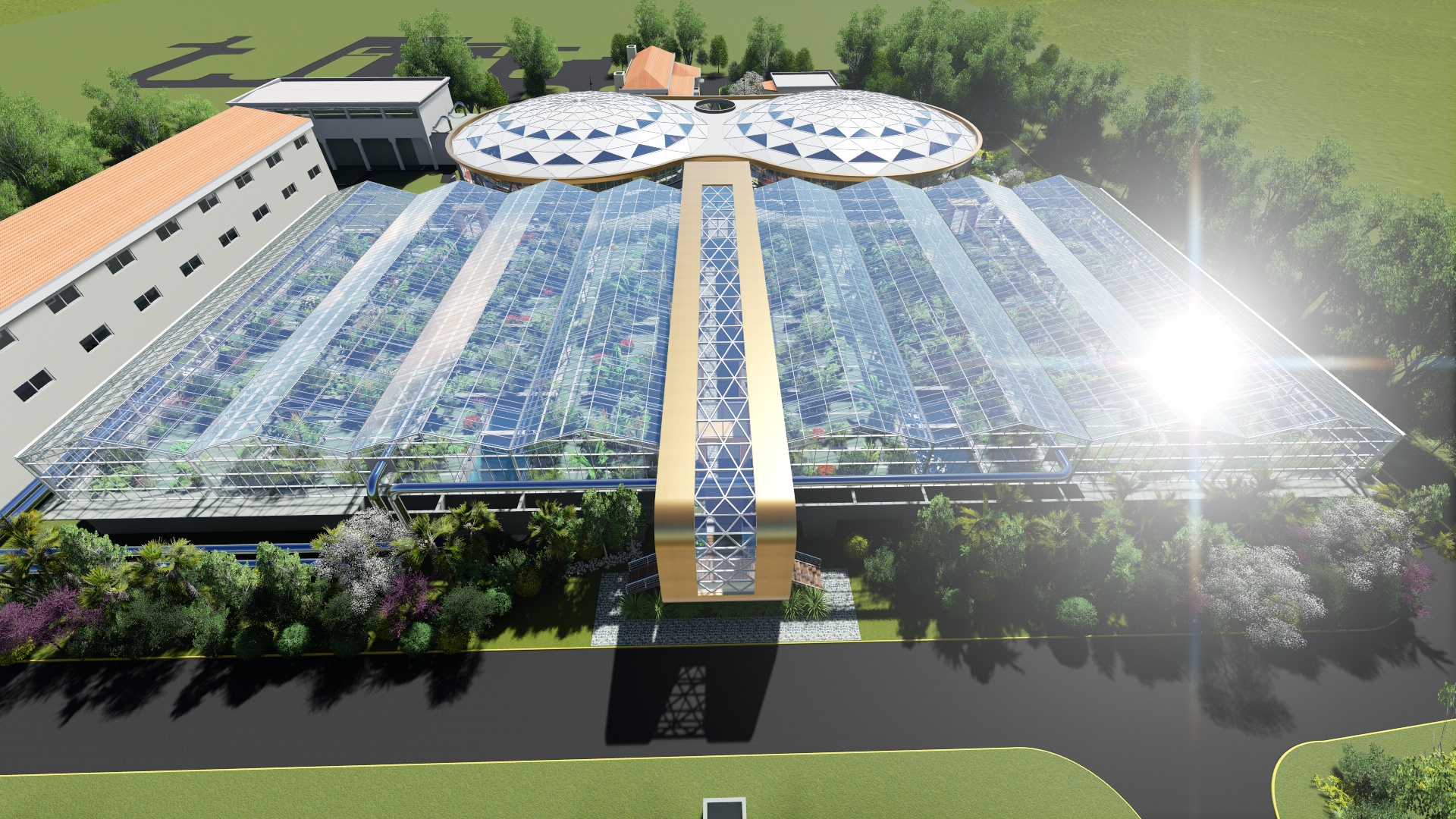

UNIQUE LOOK & FEEL

With an attractive greenhouse or shading structure design and none of the typical wastewater treatment plant odors, the garden-like appearance of an Organica facility offers a positive “psychological” footprint. This means a pleasant impact on the surrounding environment which invariably means increased property values around the plant.

RESILIENT AND STABLE SYSTEM

The use of root structures as a biofilm carrier in the Organica FCR results in a substantial increase in the diversity of microorganisms present in the system. This enhanced diversity creates a highly stable system that can adapt to unexpected fluctuations in the loading of the influent wastewater.

Applications

Municipal Wastewater Treatment

Organica plant in a suburb

Vancouver, Canada

- Wastewater treatmen can occur in dense city neighborhoods, minimizing the number one cost in wastewater infrastructure: the piping network.

- Treatment close to the waste source creates opportunities for localized water reuse, thereby decreasing pressure on drinking water infrastructure.

- Urban landscape is actually positively impacted by the presence of ‘Urban Water Gardens’.

Municipal Upgrade

40 000 m3/ day municipal Organica upgrade

Shanghai, China

- Upgrades of existing wastewater treatment facilities can increase capacity, improve effluent quality, and decrease operational costs.

- In cases where the city has developed around the old wastewater treatment facility, the technical improvements from upgrades are coupled with a transformation from industrial to natural, enhancing neighborhoods and improving the surroundings.

Real Estate Development

Organica water resource facility in the

middle of a real estate development

China

- With a small building envelope, beautiful garden aesthetics, and no odor, land value is maintained and, in many cases, even improved.

- Simple operation and lower energy consumption along with on-site water reuse opportunities will bring savings over time, and make any development much more sustainable.

Industrial Parks

The Organica Facility in the middle of a traffic circle is treating and recycling the water for irrigation

Hainan Island, China

- Treated effluent is of a high quality and local reuse needs can easily be met without additional treatment.

- Social acceptance of wastewater reuse is facilitated by the incorporation of nature – a thriving healthy garden – in the facility.

What do we do to make it happen?

WE SUPPLY WITH THE FOLLOWING COMPONENTS:

Engineering support – this ensures the integration of disciplines, and forms the basis of our process guarantee

When cooperating with a Partner, both on proposal and project implementation phases, Organica devotes a full team of dedicated engineers that are able to adapt to Partner´s specific support needs to create a highly-detailed engineering package. This can cover all the technical aspects/disciplines of engineering for the complete wastewater treatment plant: process design, detailed mechanical engineering, control and instrumentation, and civil & architectural design.

In addition to the above, thanks to Organica’s highly automated process modelling capabilities, design/engineering software and specialized engineers, the engineering documents are generated in a very short timeframe, ensuring both optimized design and on-time delivery.

Everything that is in the reactors (these components to ensure that the process works as intended)

- Biomodules – engineered media blocks within the reactors, enabling large quantities of biomass to grow and remain active.

- Plant racks – these supports natural (plant roots) biological media in the form of a beautiful garden bed on the reactor surface.

- Aeration panels – specially designed to snugly fit beneath each biomodule, enhancing hydraulic mixing and oxygen transfer efficiencies.

Discfilters – Specially designed as a small footprint phase-separation step directly after the biological reactors, which ensure compliance with strict effluent TSS requirements.

Control & Instrumentation – integrated sensors and software package to ensure efficient operation.

Commissioning support / supervision – to ensure process performance and secure process guarantee delivery.