Services

Introduction

With a unique combination of process engineering and operational, control and system integrator expertise, we can easily support those partners who operate existing plants and want to improve operational efficiency. This service is technology agnostic; thus, we bring these benefits to any treatment technologies.

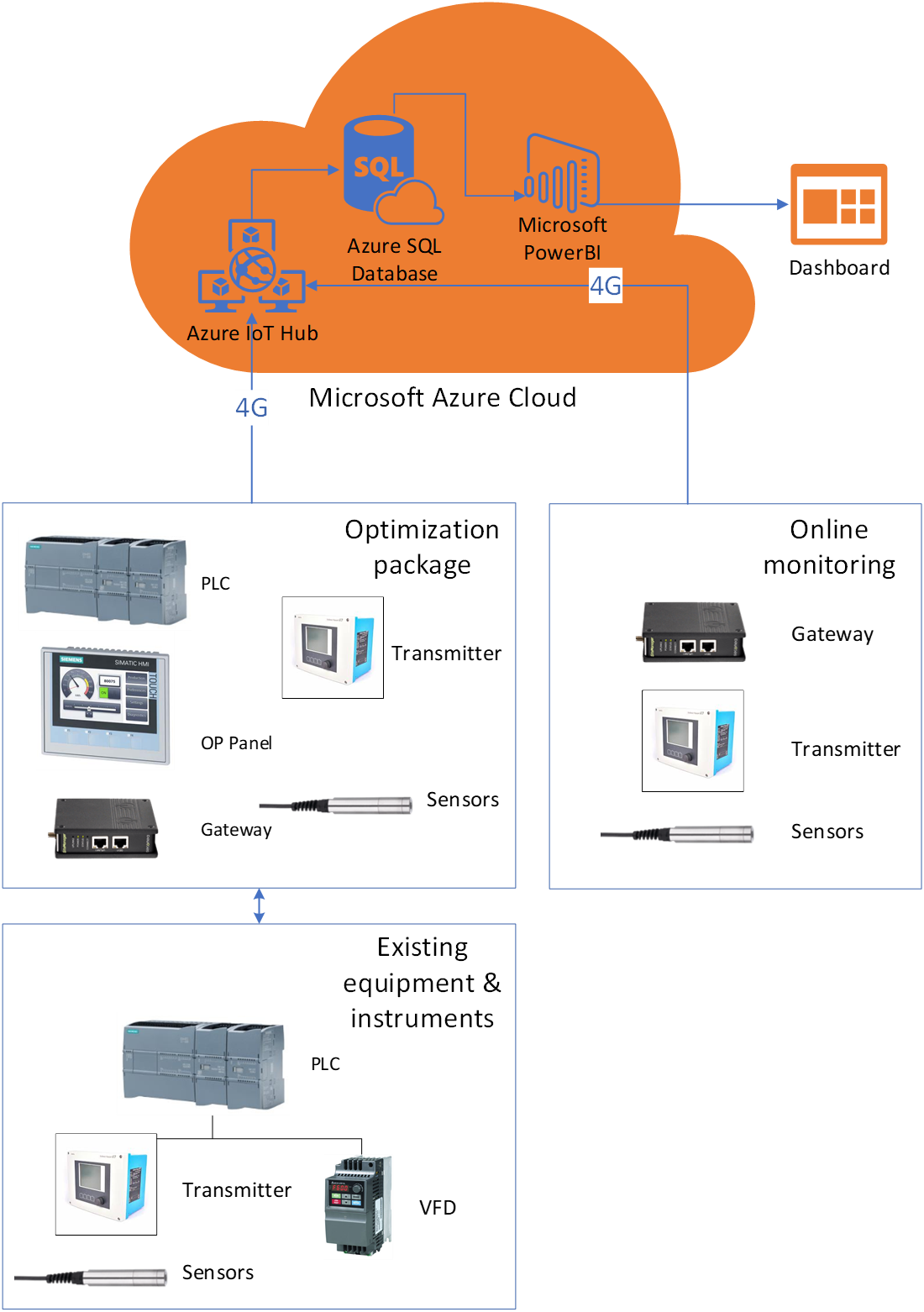

Services range from on-the-ground support to remote cloud-based reporting and analytics:

- Full O&M of treatment plants

- Optimization packages to reduce energy use, sludge production or chemical use

- Upgrade of existing control systems and control strategies

- Digital Services: data acquisition, data analysis and operational efficiency improvements to save operational cost

We start with identification and analyzation of local problems with operators. We follow by combining the right level of sensors, software and expertise to solve the issue and define the necessary capital to ensure achieve adequate return on investment.

Benefits of Digital Services

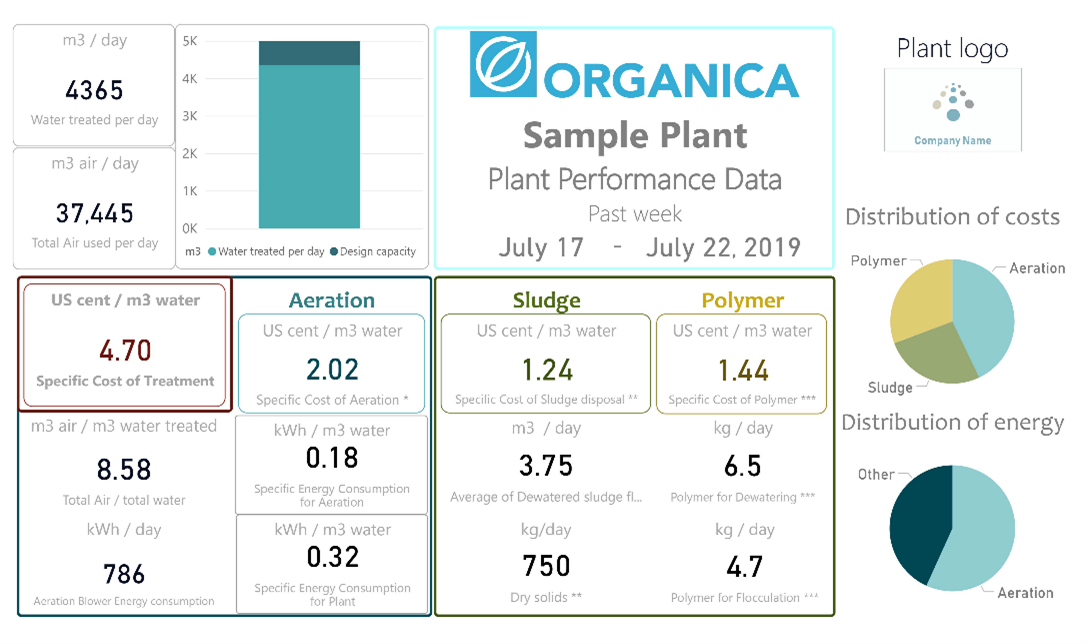

- Reduced operational expenses by at least 15%

- Improved equipment lifecycle

- Assured effluent compliances

- Reporting tool to help decision making

- Process and Control helpdesk

Sample of a weekly report dashboard

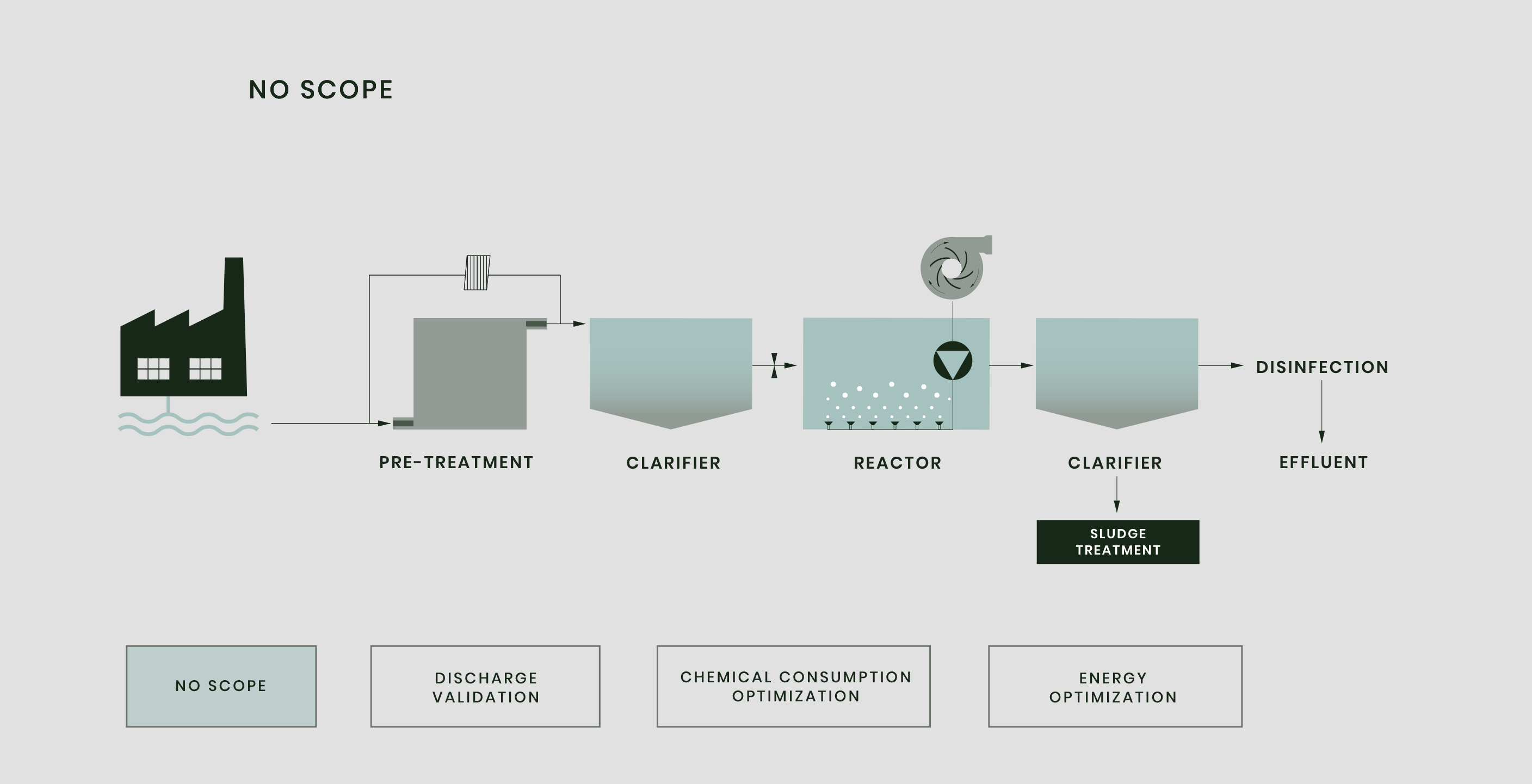

Scopes of Services

SERVICE APPLICATIONS

1. UPGRADING AGING FACILITIES

Many facilities face operational difficulties as they age and civil works and equipment quality deteriorate. This causes high costs and may significantly reduce operational uptime. By implementing digital components, a more streamlined treatment process can be created, not only reducing operational expenses but ensuring the facility meets local effluent discharge limits.

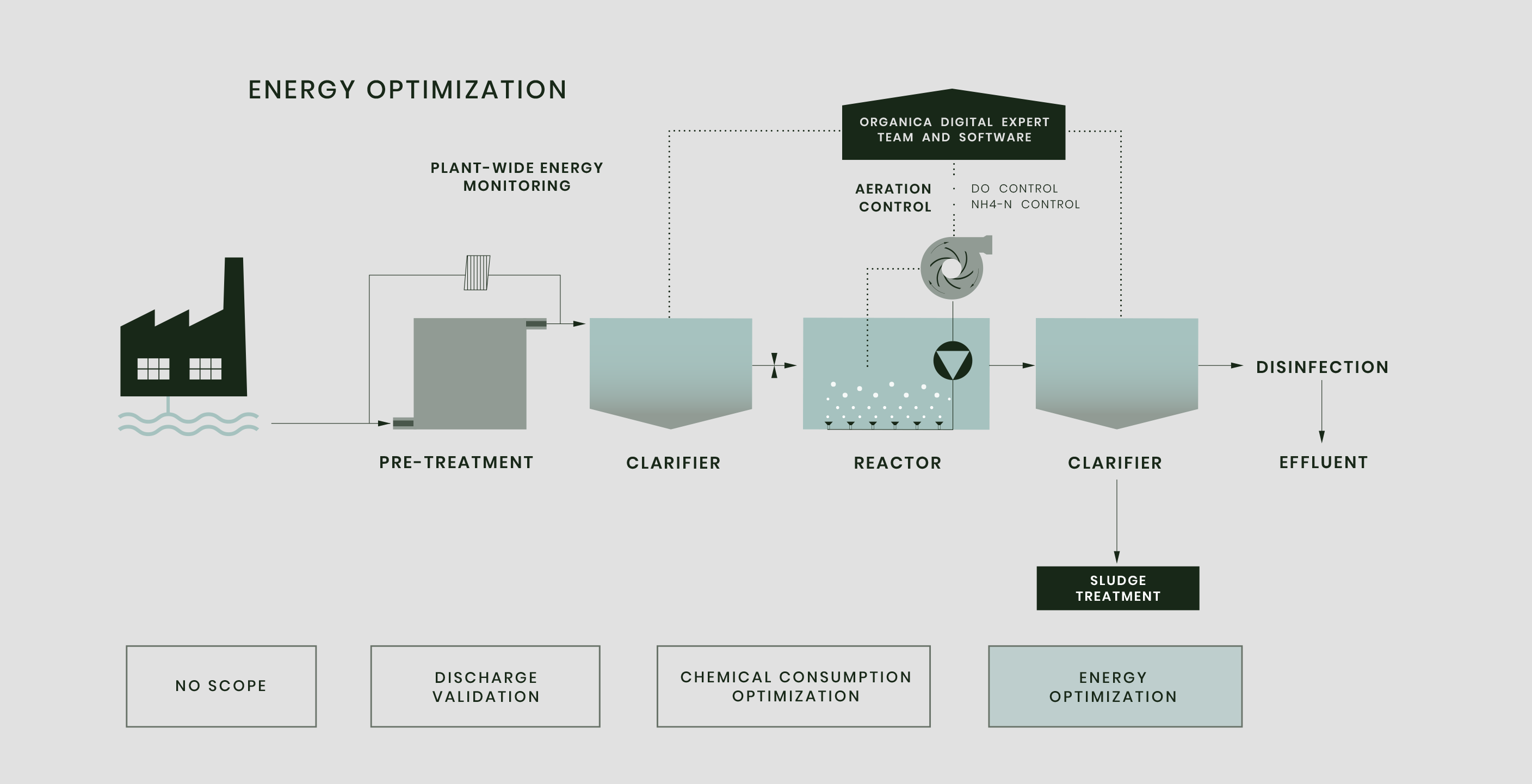

AERATION OPTIMIZATION

Aeration consumes 60-75% of the energy used at an average WWTP, thus achieving savings – while ensuring compliance – is always welcome by operators. By automating the aeration, it is expected to save energy by adjusting the required settings based on real-time data:

- Blowers – frequency, pressure or Most Open Valve (MOV) control

- Valves – opening position control

- Airflow control at aerobic stages

- DO control at aerobic stages

- Ammonia control in aerobic stages

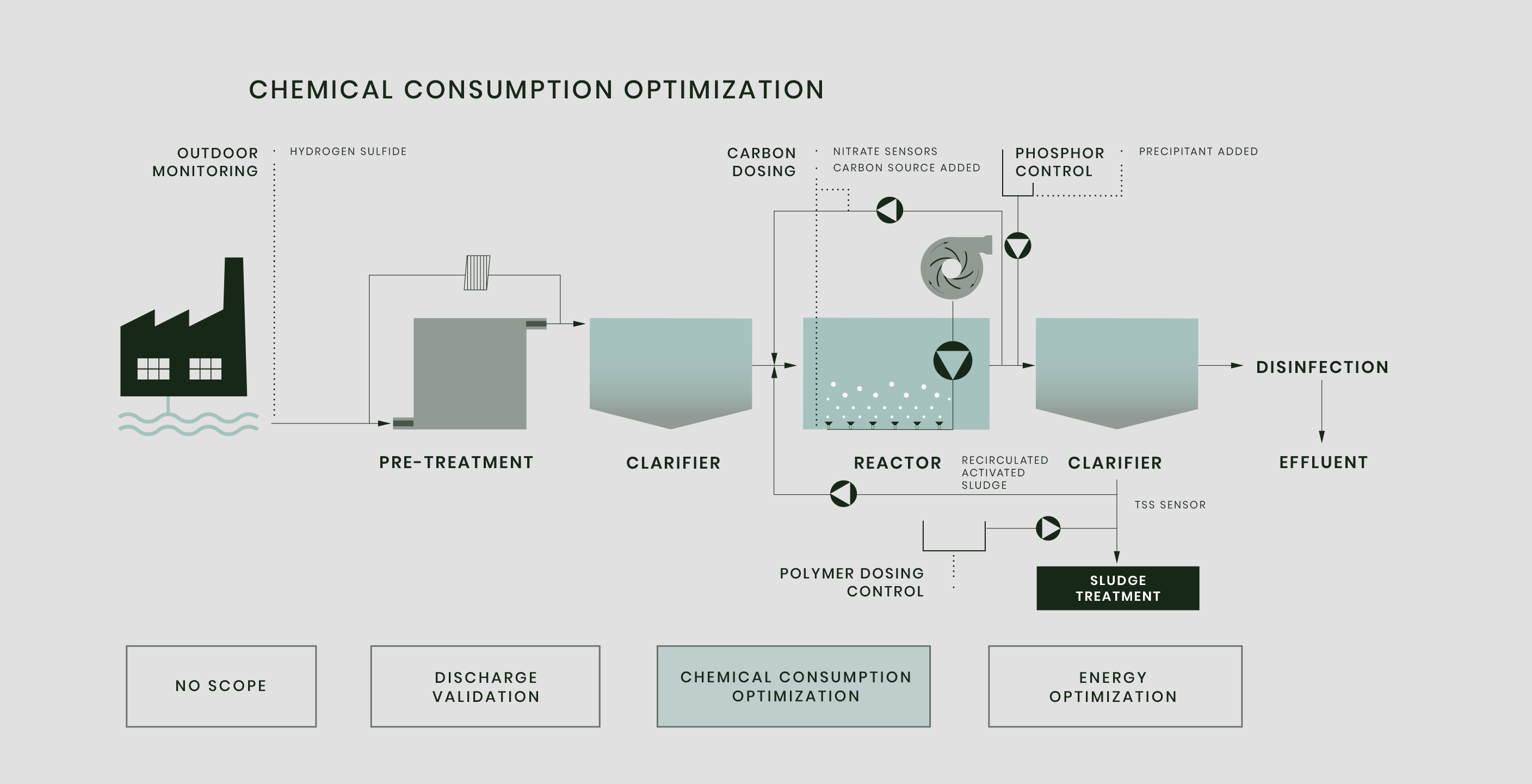

SLUDGE LINE OPTIMIZATION

Sludge dewatering is a complex part of the treatment process and can vary a lot depending on the onsite conditions, type of equipment and chemical used. By applying optimized and automated control of the sludge dewatering and wasting, along with proper chemical selection, the entire process can be operated more efficiently and by this way significant savings are expected.

- Polymer selection – series of tests to be carried out to select the most cost efficient polymer

- Sludge flow rate control – direct control of feed pumps

- Polymer dosing rate control – direct control of dosing pumps

- Sludge : polymer ratio control – installing flow meters would enable this option

- Floc stability control – special solution would improve floc characteristics

- Dewatering unit parameter optimization (if applicable)

- Other sludge line related optimization, such as clarifier wasting, sludge thickener and sludge holding tank operation

CHEMICAL PHOSPHOROUS REMOVAL CONTROL

Phosphorous control is important at WWTPs with P limit which is usually not optimized or controlled tightly, plants are rather overdosing chemical to ensure compliance By applying an automated solution, the plant can cover fluctuations in influent flow rate and the amount of phosphorous to remove to ensure compliance.

- Frequency and flow rate control – direct control of dosing pumps

- Influent flow proportional control – chemical dosing rate control based on influent flow rate

- Phosphorous control – chemical dosing rate control based on effluent P concentration

POLYMER DOSING OPTIMIZATION

The unified control of polymer dosing along the sludge line, combined with the installation of Turbidity and Total Suspended Solids sensors in the clarifiers and chlorination tanks, helps operators get a clear view of facility performance, with a good overview of operational metrics and analytics. This way, secondary clarifier operation can be enhanced with the compliance of final effluent solids discharge.

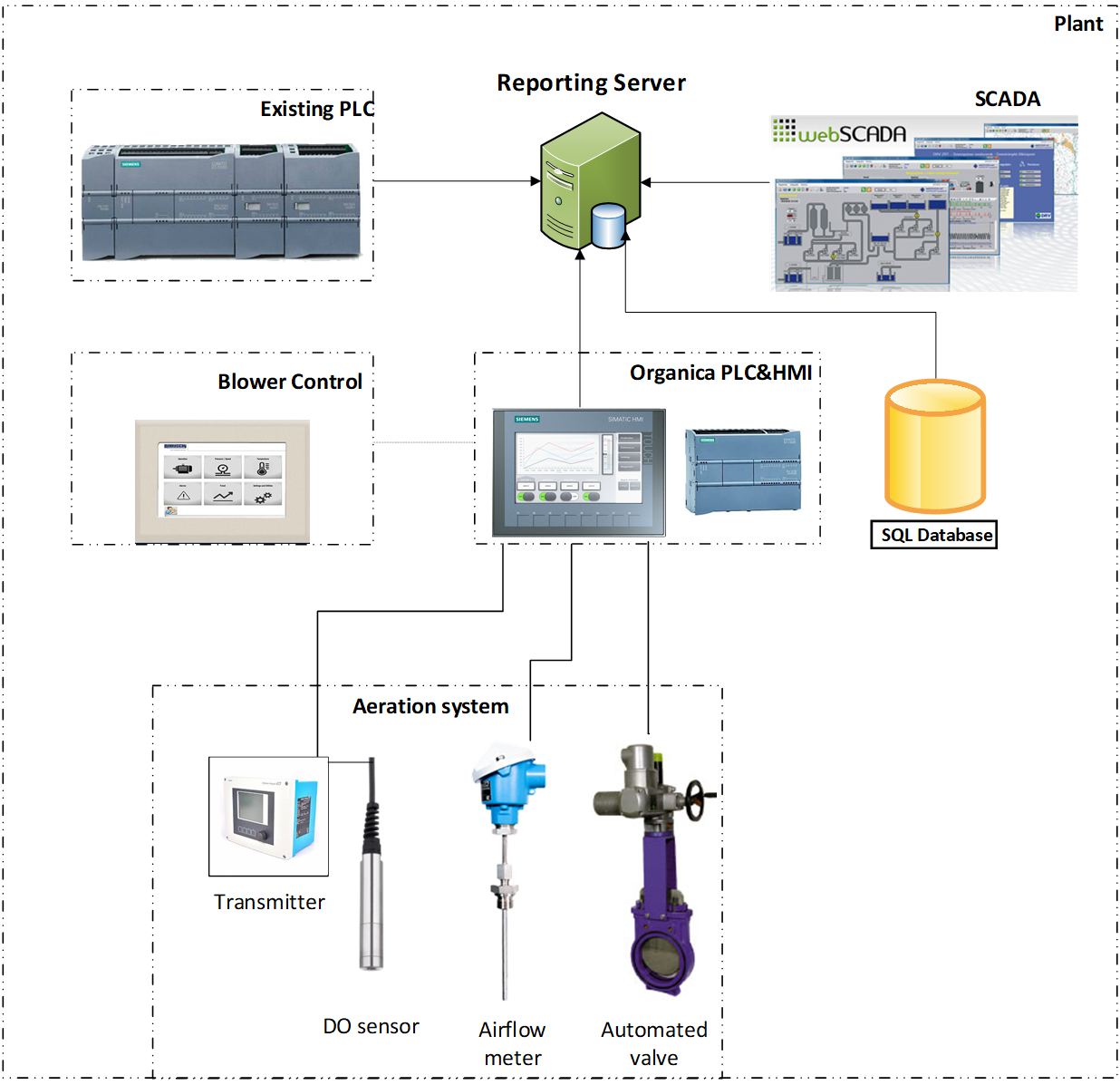

REFERENCE: AERATION CONTROL UPGRADE IN A WWTP IN CENTRAL HUNGARY

An outdated aeration system in municipal WWTP was upgraded in order to save on aeration energy costs. The old, one-section system was split up to two sections, with separately controllable valves and separate DO measurements. A DO-airflow-valve aeration cascade control system was implemented, integrated with blower control based on MOV (Most Open Valve) principles.

Additionally, a reporting server was installed at the plant which included not only the aeration but all systems at the plant. The automatically generated reports containing customized calculations enabled the operators to analyze data differently and draw conclusions about the performance of their plant.

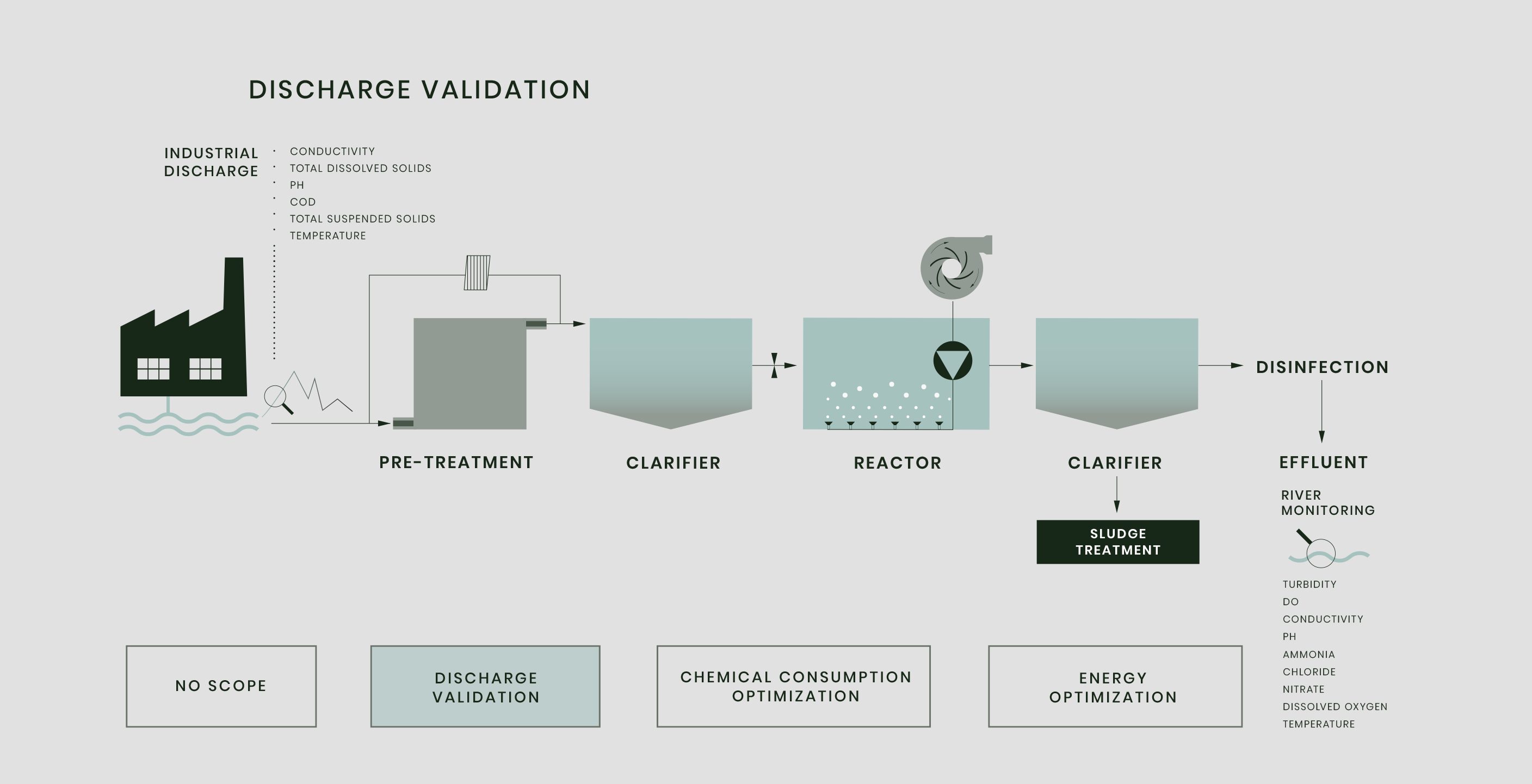

2. MONITORING STATIONS

In the age of Industry 4.0, with the advances in online sensor technology, real-time monitoring of several environmental parameters became possible. Monitoring became possible not only inside the WWTPs, but in the sewer system, in their discharge channels and in the recipients of treated wastewater as well.

INDUSTRIAL DISCHARGE MONITORING PACKAGE

Continuous monitoring on industrial discharges allows municipalities to be aware of sudden overloads and toxic events to the sewer system and eventually to municipal wastewater treatment plants. Monitoring maps out notorious and hidden illegally discharging facilities and helps protecting assets from harmful overloads resulting a sustainable and safe operation of the wastewater utilities.

Organica provides the data needed and takes care of the technical complexities of monitoring stations. Included is location selection, engineering of the physical solution, selection of sensors, data collection, data analysis, and sensors maintenance.

RIVER AND LAKE MONITORING PACKAGE

Why monitoring of pollutants in rivers, lakes and ponds is important?

- Environmental Quality Surveillance: To assess the effectiveness of wastewater management programs in the river basins

- To classify the environmental resources: Planning for the development and utilization of a water resource, necessary to classify rivers according to its quality and prospective uses.

- Collection of baseline data: To collect necessary data regarding the natural quality of water body

- Investigating cases of pollution event and providing effective corrective measures

WHAT CAN WE MEASURE?

The monitoring system is capable of the measurement of multiple parameters integrated in a single sensor, called multiprobe. The following options are available to measure the parameters which will provide a very clear indication of water quality:

- Biological Oxygen Demand (BOD)

- Chemical Oxygen Demand (COD)

- Fecal Coliforms

- Turbidity / Total Suspended Solids (TSS)

- Dissolved Oxygen

- pH / ORP

- Temperature

- Conductivity / Salinity / Total Dissolved Solids

- Ammonium (NH4-N)

- Nitrate (NO3-N)

- Chloride (Cl-)

- Water depth

- Oil in water

Additional, less typical parameters, measured by ionselective electrodes or fluorometers can also be included in the measured parameter list.

REFERENCE: EFFLUENT DISCHARGE MONITORING IN INDONESIA

A remotely accessible monitoring station was installed to the effluent of an Indonesian industrial WWTP to monitor suspended solid, organic content, ammonium and pH levels in their discharge. Using an integrated telemetry unit (basically an industrial PC) the measured data is transmitted real-time to a cloud database. This data can be monitored on the Organica Online Platform where additional analytics and alarm notifications can be set up, in addition to automatically generated reports.