Steve joined Organica Water in 2017 as VP of Digital Services with responsibility for strengthening and growing the Wastewater Treatment Plant Design Generator software and Operational Supervision & Process Optimization Services.

Prior to joining Organica, Steve was the business development leader at Suez Water Technologies & Solutions (formerly GE Water). In this role, Steve provided strategic corporate direction and program management for the business’s digital initiative. Steve is as a member of the Water Environment Federation (WEF), the Smart Water Network (SWAN), and the American Water Works Association. Additionally, he works with other various associations and utilities to propel digital water innovation. Steve earned a Bachelor of Science degree in business management from Kutztown University in 2005 and has over 12 years of experience in sales, operations, marketing, service optimization, asset performance management and software as a service business model development.

The Water Network sat down with Steve in 2018, to talk about Organica Water and creating digital and treatment innovation within the industry, in their exclusive ‘In Conversation With’ series:

Q: Thank you for taking the time to talk to us, Steve. Would you please start by telling us about your professional background and Organica Water?

A: Thank you for the opportunity to talk with the Water Network community. I have been in the water industry for roughly 15 years and I have had the opportunity to work across all industries, municipalities and coving equipment. automation, chemical, service and digital. Through this time in a large organization, I grew to enjoy the innovation that is occurring within the water space. Joining Organica Water as the VP of Digital Services is allowing me to apply my experience and boost the already innovative Organica Product with Digital Innovation.

Organica Water is a global provider of innovative solutions for the treatment and recycling of wastewater. Over the past two decades, Organica has developed a truly unique approach, enabling customers all over the world to address urban water challenges in a cost and resource efficient manner. Organica’s solutions are all founded on the fundamental belief that nature provides the most efficient means to treat wastewater, offering significant cost savings compared to other solutions, and harmonious integration into modern urban lifestyles.

Q: What are “water reclamation gardens” and how did the idea come to life?

A: Urbanization is a simple, unstoppable theme in modern life. People move to cities to live, making these already vast communities larger and larger. The simple equation goes: more people need more space and will create more wastewater. In just years, wastewater treatment plants built on the outskirts of the city, are going to be overloaded and surrounded by the city. A highly unsustainable approach. So why place them there? Why couldn’t we treat the wastewater at the source? The answer is, these facilities take up vast amounts of space and cannot be integrated into a city’s landscape. Just ask yourself the question, would you live with an industrial looking wastewater treatment facility right across the street? Probably not! So, let’s change this approach! And so, the Organica Solution was born.

Q: Regular wastewater treatment plants take up a lot of space but Organica managed to reduce the physical footprint and eliminate the odors. How? What makes Organica’s wastewater treatment different?

A: Organica FCR is a type of fixed-film system offering substantial benefits, both technical and economic, over alternative solutions. Like all fixed-film systems, Organica Food Chain Reactor (FCR) is based on the same activated sludge process that has been used in wastewater treatment for nearly a century, whereby microorganisms and bacteria (collectively referred to as biomass) consume and metabolize or oxidize the contaminants available in wastewater.

- Organica FCR drastically improves this process by leveraging a fixed-bed biofilm (attached growth, and not floating suspended in the water) that grows on both natural (plant) and engineered (patented biofiber media) root structures in a cascading reactor design, allowing a much greater quantity and diversity of organisms to thrive in the same physical space.

- The larger and more diverse biomass per unit of reactor volume results in a significantly smaller physical footprint (reducing construction costs), as well as improved stability, increased nutrient removal performance, and reduced energy consumption.

- Each Organica FCR is housed in an aesthetically-pleasing, odorless structure (greenhouse in colder climates, simple shading structures only in tropical climates) with the appearance of a botanical garden, preserving the surrounding land value and allowing the wastewater treatment plant (WWTP) to be placed directly adjacent to the wastewater source, thereby greatly reducing infrastructure costs

Q: How many liters per day can one Organica’s facility treat depending on its size? How much of the treated water can be recycled?

A: Organica wastewater treatment facilities, similar to it’s Conventional Activated Sludge counterpart, are highly scalable, enabling the clients to treat a wide range of effluent capacities. From a numbers perspective, we already have treatment plants ranging from 100 m3/d to 80,000 m3/d. This versatility enhances the concept of localization by enabling the Organica team to optimize for the wide range of situations and requirements necessary to build wastewater facilities in the middle of cities, close to the source of the wastewater.

Organica’s wastewater treatment plant can be located in the middle of the city and it is actually a desirable location to live next to. As populations continue to grow, cities – especially in the developing world – are becoming more and more crowded, while in other parts of the world “urban sprawl” is graying the lines between what is “urban” and “suburban.”

As a result, the land is becoming scarcer and land values near population centers continue to rise. Governments can no longer afford to waste valuable space on WWTPs and the odor and unattractive aesthetics that causes people to live far away from them, not to mention the high cost of building and operating the infrastructure to take the wastewater and effluent to and from the remote WWTP location.

With an attractive greenhouse design and none of the typical wastewater treatment plant odors, the garden-like appearance of an Organica FCR offers a significantly reduced geographic and “psychological” footprint, dramatically reducing infrastructure costs by allowing wastewater to be treated close to the source.

Q: What is the footprint of Organica’s wastewater treatment in comparison to conventional plants?

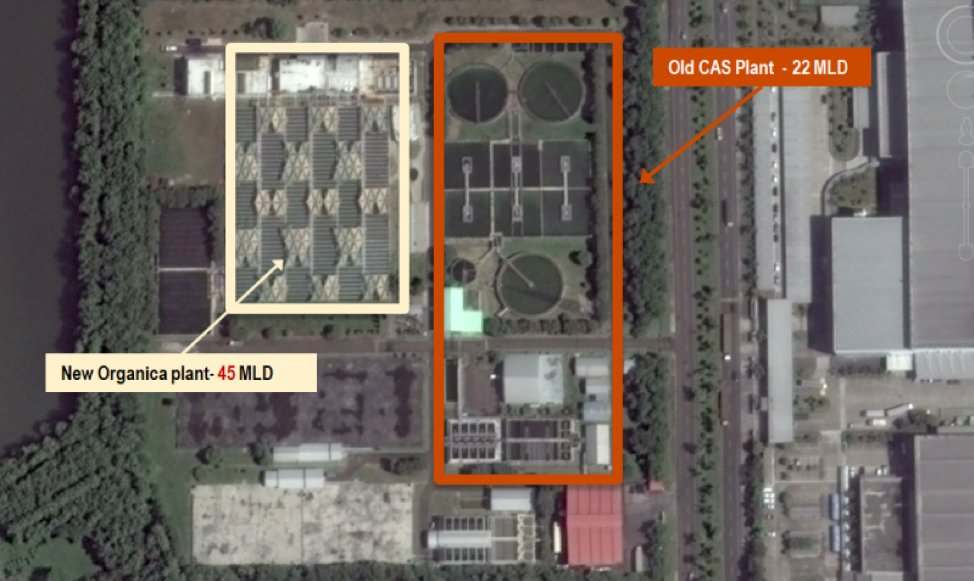

A: Due to the fixed film nature of the Organica FCR Solution, the concentration of biomass is typically 3 to 4 times larger than in a Conventional Activated Sludge system.

As a result of this larger quantity of biomass (hungry mouths) in one cubic meter of reactor volume and Organica’s two decades of experience with optimal architectural designs, the physical footprint of Organica facilities is up to 50% smaller than conventional activated sludge plants. With land values in urban areas ever increasing, the small footprint helps to drive down capital costs.

Q: What is necessary for the maintenance and how much energy does Organica’s wastewater treatment plant use?

A: On average, about 50% of the energy consumed by a wastewater treatment plant (WWTP) is used by the blowers to pump air into the water and keep the biomass alive and in suspension.

As the vast majority of the biomass in an Organica FCR is attached (as opposed to in suspension), the suspended solids concentrations are lower in each reactor. Since oxygen transfer in clearer water is more efficient, this means that less air is required to keep the ecosystem alive in an Organica FCR.

Thus, the blowers in an Organica FCR consume significantly less power than those in a conventional solution for the same quality and quantity of wastewater, resulting in – on average – 30% energy savings compared to Activated sludge.

Training of operators of greenfield Organica facilities usually require a relatively low 2 days as all Organica-powered WWTPs have a comparatively higher degree of automation, thus reducing operator interface and hence personnel requirement on site. Depending on the size of the WWTP a few people can easily run the plant with a few hours of work every day.

Q: Could you give us a few examples of Organica’s successful decentralized wastewater treatment plants around the world?

A: Currently, there are over 110 Organica facilities around the world, either operational or under construction. Some of the most notable references are below:

- Sechelt, Canada: This 4,000 m3/d greenfield project was created due to the growing stress on the municipality’s old, outdated sewage network, which consisted of the uphill transportation of wastewater to an old CAS facility. Due to the aesthetic and odorless aspects of the Organica Solution, a new facility was built in the very middle of the city, at the source of the wastewater, saving land value by having a compact footprint, reducing OPEX and most importantly, significantly reducing CAPEX by eliminating the need of excessive sewer infrastructure work.

- South Pest, Hungary: This enormous, old wastewater treatment facility was created in the 1960s to treat approximately one third of the capital’s wastewater, however, due to the urbanization induced growth of the city’s wastewater generation and the introduction of a waste-to-energy facility in the vicinity of the site, the WWTP started experiencing serious malfunctions ranging from odour problems and foaming issues to not meeting discharge standards at all. By enhancing the biological treatment phase with the Organica FCR technology, the hydraulic capacity of the facility grew to 80,000 m3/d, eliminating odor issues and performing perfectly, even under stress load conditions.

- Gencay, France: Located in Western France, Gençay is a small community in a beautiful location with a 13th-century fortress – Chateau de Gençay – in its center. Facing new water quality standards, Gençay, together with the neighboring town of Saint-Maurice-La-Clouere, decided to find a wastewater solution that fits into the local setting, without ruining the scenic landscape, something that is of high touristic interest in the region. By creating this Organica powered 600 m3d facilities, the municipalities now generate crystal clear effluent, while preserving the touristic scenery of the region.

Q: Do you think decentralized wastewater treatment in general, and “water reclamation gardens” will gain in popularity in a couple of following decades?

A: With Urbanization in mind, a highly different, more sustainable approach has to be considered, where wastewater treatment plants are not a thing of necessity out of sight, out of mind. The Organica approach gives the community the ability, to transform something people previously considered an industrial area far on the outskirts of the city, into a “Water Reclamation Garden”. A little green heaven, bringing color the city landscape. This does not only change the methods we use to treat wastewater but redefines the general perspective on wastewater treatment as a whole.

Q: What are the future plans for Organica?

A: Organica Water is still a relatively young company, with geographies still untouched. As such, the company is very focused on trying to bring the technology and this new perspective to countries in dire needs of wastewater treatment. We are expanding into the software with a set of Digital Services that will help the greater water industry move forward by reducing the hours of engineering needed to design a plant to assist with optimization of existing plants. By utilizing Digital Services, the industry can take on more innovation.

Q: Finally, do you have a take-home message for our members?

A: Water is scarce and even as we are speaking, available water resources are reducing. It is our job to put the spotlight on wastewater treatment, and turn the “out of sight, out of mind” mindset on its head because the key for a sustainable future lies in wastewater treatment. A smarter, localized wastewater treatment.

Original interview courtesy of The Water Network.